Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 25, 2024 Visit:170 Source:ZCM

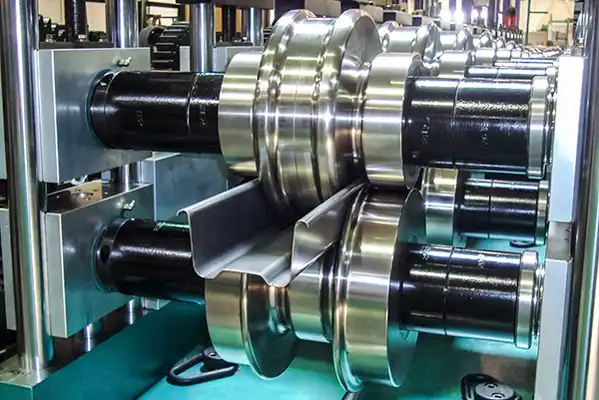

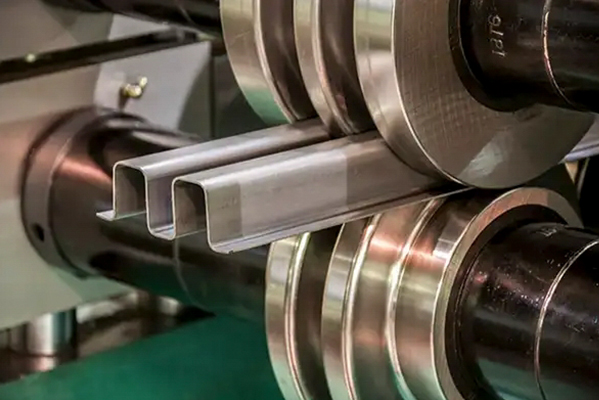

Roll forming machines have become indispensable tools in a wide range of industries, playing a crucial role in the fabrication of various products and components. Their ability to shape metal into intricate and precise forms makes them indispensable in multiple sectors, from automotive and aerospace to construction and furniture manufacturing. Here, we explore the diverse applications of roll forming machines across these industries.

Automotive Industry

In the automotive industry, roll forming machines are used to produce a variety of components, including frame rails, door beams, roof rails, and bumpers. The precision and consistency of roll forming ensure that these components meet the stringent safety and performance standards required by the automotive sector. Additionally, roll forming machines can handle a wide range of materials, such as high-strength steel and aluminum, allowing manufacturers to optimize the weight and performance of automotive components.

Aerospace Industry

The aerospace industry also relies heavily on roll forming machines. In this sector, roll forming is used to produce components such as aircraft fuselage sections, wing spars, and landing gear components. The precision and repeatability of roll forming machines are essential in ensuring that aerospace components meet the rigorous safety and performance standards required for flight. Roll forming also allows manufacturers to work with lightweight, high-strength materials, such as titanium and aluminum alloys, which are crucial in reducing aircraft weight and improving fuel efficiency.

Construction Industry

In the construction industry, roll forming machines are used to produce a variety of building components, including roofing, siding, and structural steel framing. Roll formed components are known for their durability, strength, and resistance to weather and corrosion. This makes them ideal for use in both residential and commercial construction projects. Roll forming machines can also produce custom-sized components, allowing builders to optimize the design and efficiency of their buildings.

Furniture Manufacturing

The furniture manufacturing industry also benefits from the versatility of roll forming machines. Roll formed metal tubes and profiles are commonly used in the production of furniture frames, legs, and supports. These components are strong, lightweight, and easy to assemble, making them ideal for use in a wide range of furniture types, from office chairs and desks to dining tables and beds. Roll forming machines can also produce decorative and functional features, such as embossed patterns and curved profiles, adding aesthetic appeal to furniture designs.

Appliance Manufacturing

Roll forming machines are also used in the manufacturing of appliances, such as refrigerators, washing machines, and dishwashers. Roll formed components, such as door frames, handles, and brackets, are essential in the construction of durable and reliable appliances. Roll forming machines can produce these components with precise dimensions and finishes, ensuring that appliances meet consumer expectations for quality and performance.

Agricultural Equipment

In the agricultural industry, roll forming machines are used to produce components for farming equipment, such as tractor frames, planter boxes, and livestock trailers. Roll formed components are robust and durable, withstanding the rigors of agricultural use. Roll forming machines can also produce components with specialized features, such as drainage holes and reinforcement structures, enhancing the functionality and longevity of agricultural equipment.

Transportation and Logistics

The transportation and logistics industry also relies on roll forming machines to produce components for vehicles such as trailers, shipping containers, and railway cars. Roll formed components are strong, lightweight, and corrosion-resistant, making them ideal for use in transportation and logistics applications. Roll forming machines can also produce components with specialized features, such as reinforced corners and locking mechanisms, enhancing the security and durability of transportation equipment.

In conclusion, roll forming machines have a wide range of applications across diverse industries. Their precision, versatility, and ability to handle a variety of materials make them indispensable in the fabrication of components and products in sectors such as automotive, aerospace, construction, furniture manufacturing, appliance manufacturing, agricultural equipment, and transportation and logistics. As these industries continue to evolve, roll forming machines will play an increasingly important role in meeting the demands of the market.