Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 10, 2024 Visit:231 Source:ZCM

In the manufacturing industry, the production of heavy gauge roll-formed products has always been a critical aspect, requiring precision, efficiency, and reliability. A professional manufacturer dedicated to this field can significantly enhance the efficiency of the heavy gauge roll forming process, ensuring that high-quality products are produced in a timely and cost-effective manner.

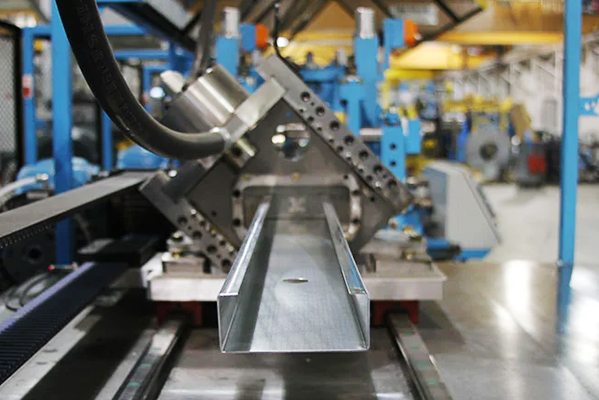

Heavy gauge roll forming involves shaping thick metal sheets into desired shapes and profiles using a series of rolling dies. This process is complex and demands expertise in both machinery and material science. A professional manufacturer possesses the knowledge and technology to optimize the entire production line, from raw material selection to final product output.

One of the key factors contributing to efficiency in heavy gauge roll forming is the precision of the rolling dies. A professional manufacturer invests in advanced tooling and die design techniques, ensuring that the dies are accurately engineered to produce the desired shape with minimal waste and maximum consistency. This precision not only boosts production speeds but also reduces the need for secondary operations, such as trimming or grinding, further enhancing overall efficiency.

In addition to precision tooling, a professional manufacturer also focuses on the automation and integration of the roll forming process. Advanced automation systems can monitor and adjust the process in real-time, ensuring that the material is fed correctly, the dies are aligned properly, and the formed product meets specifications. This level of automation reduces human error and downtime, allowing for continuous and consistent production.

Moreover, a professional manufacturer is likely to have extensive experience working with a variety of materials and thicknesses. This expertise enables them to tailor the roll forming process to the specific needs of each project, optimizing the parameters for material flow, die engagement, and forming pressure to achieve the best possible results.

Another important aspect of efficiency in heavy gauge roll forming is the maintenance and optimization of the equipment. A professional manufacturer will have a dedicated team of technicians who regularly inspect, clean, and repair the roll forming machinery. This proactive maintenance approach ensures that the equipment operates smoothly and efficiently, minimizing breakdowns and extending the lifespan of the machinery.

In conclusion, the efficiency of heavy gauge roll forming can be significantly boosted by a professional manufacturer. With precision tooling, advanced automation, extensive material expertise, and proactive equipment maintenance, a professional manufacturer is well-equipped to deliver high-quality, cost-effective roll-formed products in a timely manner. By partnering with such a manufacturer, businesses can gain a competitive edge in the market, satisfying customer demands while maintaining profitability.