Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 25, 2024 Visit:206 Source:ZCM

In the realm of industrial manufacturing, the demand for heavy gauge roll forming machines has seen a significant surge, driven by the need for precision and efficiency across various sectors. Manufacturers of these machines have responded to this growing demand by placing a strong emphasis on customization, enabling them to cater to a wide array of applications.

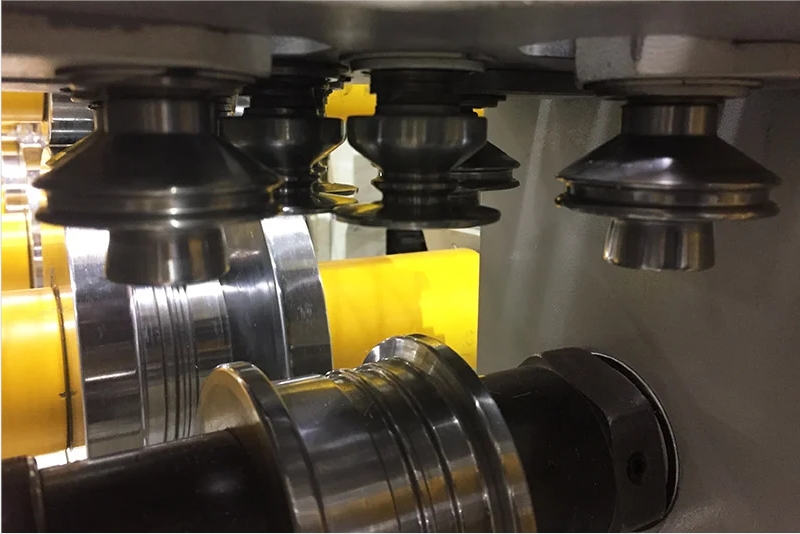

Heavy gauge roll forming is a process that involves shaping metal sheets into desired profiles using a series of rolls. This technique is particularly suited for creating strong, durable structures that can withstand significant loads and environmental conditions. From automotive parts to construction materials, the versatility of heavy gauge roll forming machines makes them indispensable in numerous industries.

One of the key advantages of customization in heavy gauge roll forming machine manufacturing is the ability to meet specific customer requirements. Different industries have unique needs in terms of material thickness, shape, and size. By offering customized solutions, manufacturers can ensure that the machines produced are tailored to the exact specifications of each project, optimizing both performance and cost-effectiveness.

For instance, in the automotive industry, heavy gauge roll forming machines are often used to produce structural components such as frame rails and roof supports. These components require precise dimensions and high strength, making customization essential for achieving the desired performance characteristics. Similarly, in the construction sector, roll formed steel is used for beams, columns, and other structural elements, where customization ensures that the materials meet the specific load-bearing and aesthetic requirements of each building project.

Customization also extends to the process itself. Manufacturers of heavy gauge roll forming machines can adjust the speed, pressure, and temperature of the rolling process to accommodate different materials and desired outcomes. This flexibility allows for the production of a wide range of profiles, from simple channels and angles to complex, multi-curved shapes.

Moreover, the customization trend in heavy gauge roll forming machine manufacturing is driven by advancements in technology. Modern CAD/CAM systems enable manufacturers to design and simulate roll forming processes with high precision, reducing the need for prototype testing and speeding up the development cycle. This, in turn, allows for quicker response to market demands and the ability to offer more innovative solutions.

In addition to technical advancements, the focus on customization reflects a shift in the manufacturing paradigm towards customer-centricity. Manufacturers are increasingly recognizing the value of building long-term relationships with their clients, understanding their unique needs, and providing ongoing support and customization services. This approach not only enhances customer satisfaction but also fosters loyalty and repeat business.

In conclusion, the trend of customization in heavy gauge roll forming machine manufacturing is a testament to the versatility and adaptability of this technology. By offering tailored solutions for diverse applications, manufacturers are able to meet the evolving needs of their customers and drive innovation in the industrial manufacturing sector. As technology continues to advance and customer expectations rise, the focus on customization will likely remain a key driver of success in this field.