Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 12, 2024 Visit:228 Source:ZCM

In the realm of manufacturing, precision is paramount. It ensures product quality, reduces waste, and enhances overall efficiency. Among the various tools and machines that contribute to this precision, heavy gauge roll forming machines stand out due to their ability to handle thick metal sheets with remarkable accuracy. This technology has undergone significant advancements, further enhancing its capacity to deliver precision in manufacturing processes.

The Role of Heavy Gauge Roll Forming Machines

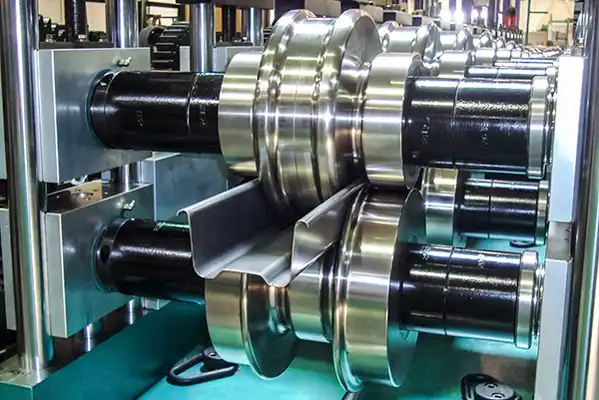

Heavy gauge roll forming machines are designed to shape thick metal sheets into desired profiles and shapes. They are widely used in industries such as automotive, construction, aerospace, and more, where durability and precision are critical. These machines operate by passing the metal sheet through a series of rollers that progressively bend and shape the material until the desired form is achieved.

Advancements in Precision Technology

Recent advancements in heavy gauge roll forming machine technology have significantly improved manufacturing precision. One key development is the integration of high-precision roller sets. These rollers are manufactured to exact tolerances, ensuring that the metal sheet is shaped consistently and accurately. The use of advanced materials, such as hardened steel and carbide, further enhances the durability and precision of these rollers.

Moreover, the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has revolutionized the roll forming process. These systems allow manufacturers to design and simulate the forming process digitally, identifying potential issues before they arise. This predictive capability enables manufacturers to optimize the roller design and process parameters, thereby enhancing precision and reducing errors.

Automated Control Systems

Another significant advancement is the integration of automated control systems. These systems, often powered by programmable logic controllers (PLCs), provide precise control over the roll forming process. They monitor and adjust the roller position, speed, and force in real-time, ensuring that the metal sheet is shaped accurately throughout the entire process. This level of control minimizes variations and inconsistencies, resulting in higher precision in the final product.

Material Handling and Feeding Mechanisms

Advancements in material handling and feeding mechanisms have also contributed to the enhanced precision of heavy gauge roll forming machines. Modern machines are equipped with high-precision feeders and conveyors that ensure smooth and consistent feeding of the metal sheet through the rollers. These systems are designed to minimize material deformation and maintain tension control, thereby enhancing the accuracy of the forming process.

In-Process Monitoring and Quality Control

In-process monitoring and quality control systems have become increasingly sophisticated, further enhancing manufacturing precision. These systems utilize sensors and cameras to monitor the forming process in real-time, detecting any deviations from the desired shape or profile. Manufacturers can then adjust the process parameters accordingly, ensuring that the final product meets the required specifications.

Conclusion

Heavy gauge roll forming machines have become indispensable in industries requiring high precision and durability in metal forming. The advancements in roller design, automated control systems, material handling, and in-process monitoring have significantly enhanced the precision of these machines. As technology continues to evolve, it is likely that heavy gauge roll forming machines will become even more sophisticated, delivering even higher levels of precision and efficiency in manufacturing processes.

By embracing these advancements, manufacturers can improve product quality, reduce waste, and enhance overall productivity. The enhanced precision of heavy gauge roll forming machines underscores the importance of ongoing innovation in the manufacturing sector, driving progress and competitiveness in a rapidly evolving market.