Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 11, 2024 Visit:235 Source:ZCM

The evolution of heavy gauge roll forming machine technology has significantly impacted the manufacturing sector, particularly in industries requiring robust and precise metal forming solutions. These advancements have not only enhanced production efficiency but also diversified the range of applications for such machines.

Historical Background and Evolution

Historically, roll forming machines were primarily used for basic shaping tasks in various industries. Over time, technological innovations have driven the development of heavy gauge roll forming machines, which are now capable of handling thicker and more durable materials. The transition from manual to automated processes has been pivotal, allowing for greater precision and consistency in product output.

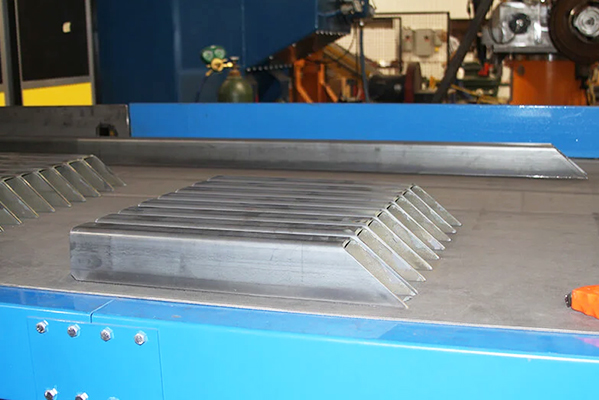

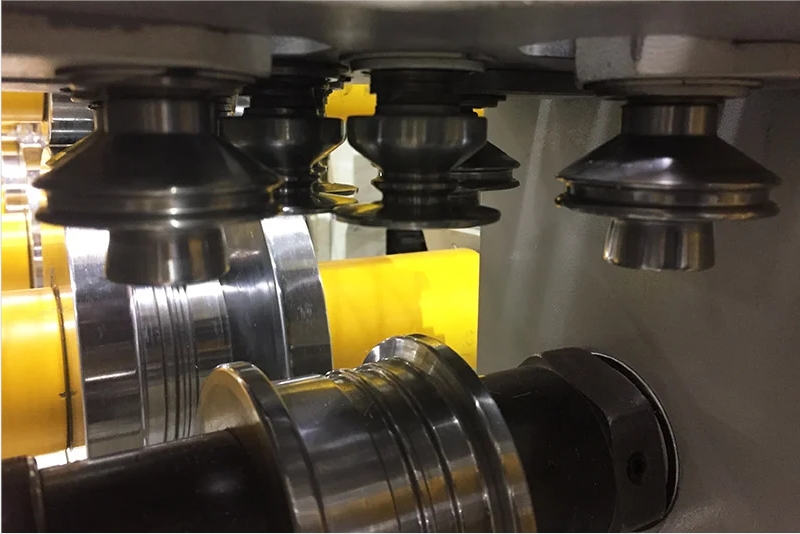

Advancements in Machinery Design

Modern heavy gauge roll forming machines feature sophisticated designs that incorporate advanced materials and precision engineering. These machines are equipped with robust frames and high-tolerance rollers, ensuring accurate forming of thick metal sheets. The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has further enhanced the precision and versatility of these machines, allowing manufacturers to create complex shapes and profiles with minimal waste.

Control Systems and Automation

One of the most significant advancements in heavy gauge roll forming machine technology is the integration of advanced control systems. These systems, often powered by programmable logic controllers (PLCs), enable precise control over the forming process, ensuring consistency and reducing the risk of errors. Automation has also played a crucial role, with many machines now capable of operating continuously with minimal human intervention. This has not only increased production rates but also reduced labor costs and improved safety.

Enhanced Material Handling Capabilities

Heavy gauge roll forming machines have also seen advancements in material handling capabilities. Modern machines are equipped with powerful feeders and conveyors that can handle thick metal sheets with ease. These systems are designed to minimize material deformation and ensure smooth, continuous feeding through the forming process. Additionally, many machines now feature automatic lubrication systems, which reduce friction and wear, thereby extending the lifespan of the rollers and other components.

Versatility and Customization

With the increasing demand for customized metal products, heavy gauge roll forming machines have become more versatile. Manufacturers can now create a wide range of shapes and profiles, from simple curves to complex geometric patterns. This versatility is achieved through the use of interchangeable tooling and adjustable roller sets, which allow for quick and easy changes in production specifications.

Conclusion

The advancements in heavy gauge roll forming machine technology have transformed the manufacturing landscape, enabling higher efficiency, precision, and versatility in metal forming processes. From sophisticated machinery design to advanced control systems and material handling capabilities, these innovations have set new benchmarks in the industry. As technology continues to evolve, it is likely that heavy gauge roll forming machines will become even more sophisticated, further expanding their range of applications and enhancing their overall performance.

The evolution of heavy gauge roll forming machine technology underscores the importance of ongoing innovation in the manufacturing sector. By embracing these advancements, manufacturers can stay competitive, improve productivity, and meet the growing demand for high-quality metal products.