Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:191 Source:ZCM

The automotive industry has consistently evolved to meet the demands of consumers and technological advancements. Among the various manufacturing processes that have contributed to this growth, the integration of heavy gauge roll formers has gained significant traction. This trend is not surprising, given the numerous benefits that heavy gauge roll forming brings to automotive manufacturing in terms of efficiency, precision, and cost-effectiveness.

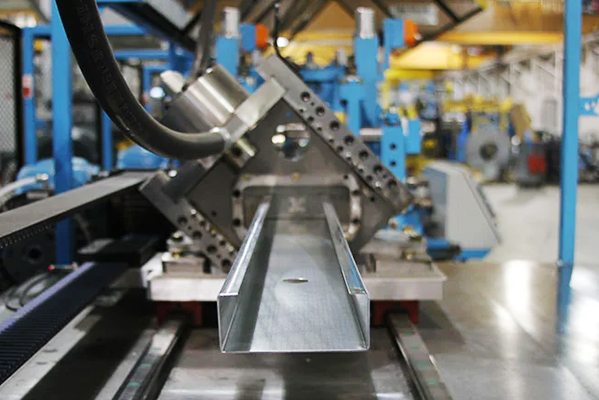

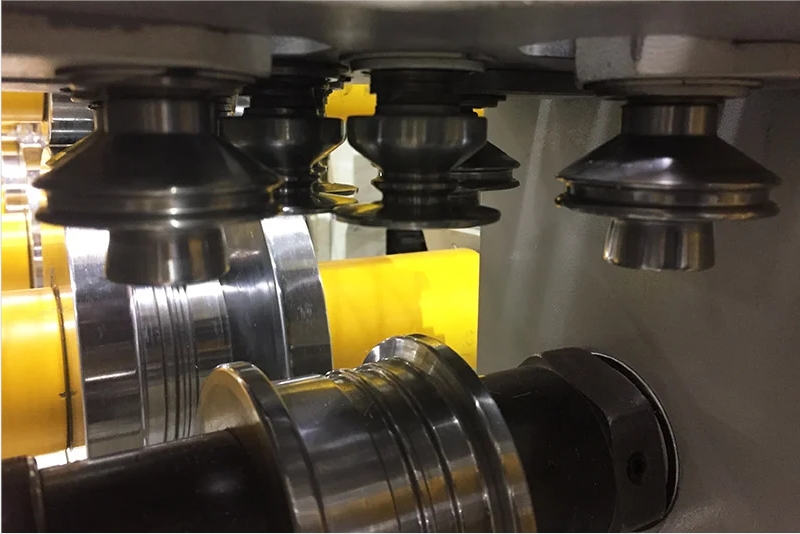

Heavy gauge roll formers are specialized machines that shape and form thick metal sheets into complex shapes and profiles. These machines are particularly suited for processing high-strength materials, which are increasingly used in automotive manufacturing to improve fuel efficiency, safety, and durability.

One of the primary reasons for the integration of heavy gauge roll formers in automotive manufacturing is their ability to produce parts with high precision and consistency. The automotive industry demands stringent quality control, and roll forming machines can meet these requirements by forming parts to tight tolerances. This precision ensures that parts fit together seamlessly, reducing the need for secondary operations such as trimming and grinding.

In addition to precision, heavy gauge roll formers offer significant cost savings compared to traditional manufacturing methods. Roll forming is a continuous process that can produce parts at high speeds, reducing labor costs and increasing throughput. Moreover, the use of heavy gauge roll formers minimizes material waste, as the process creates little to no scrap. This is particularly important in the automotive industry, where material costs can be significant.

Another advantage of heavy gauge roll forming in automotive manufacturing is its flexibility. Roll formers can be configured to produce a wide range of parts, from simple beams and brackets to complex structural components. This versatility allows automakers to respond quickly to market demands and design changes, without the need for extensive tooling investments.

The integration of heavy gauge roll formers in automotive manufacturing has also led to the development of innovative materials and designs. For example, high-strength steels and aluminum alloys, which are difficult to process using traditional methods, can be easily formed using roll forming technology. This has enabled automakers to develop lighter, stronger vehicles that meet stringent safety and fuel economy standards.

Furthermore, the automotive industry is increasingly adopting automation and robotics to improve efficiency and reduce labor costs. Heavy gauge roll formers are well-suited for integration with these advanced manufacturing systems. By automating the roll forming process, automakers can further reduce downtime, increase production speeds, and ensure consistent part quality.

In conclusion, the integration of heavy gauge roll formers in automotive manufacturing is a trend that is gaining traction for several reasons. These machines offer precision, cost savings, flexibility, and compatibility with advanced manufacturing systems. As the automotive industry continues to evolve, it is likely that the use of heavy gauge roll formers will become even more widespread, driving innovation and efficiency in the production of automotive components.