Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 14, 2024 Visit:227 Source:ZCM

In the dynamic landscape of industrial manufacturing, the role of heavy gauge roll forming machines has evolved into a pivotal one, particularly in optimizing production efficiency. These machines have transformed the metal forming process, bringing about significant improvements in speed, accuracy, and cost-effectiveness. This article explores how heavy gauge roll forming machines contribute to enhancing production efficiency across various industries.

Precision and Consistency in Manufacturing

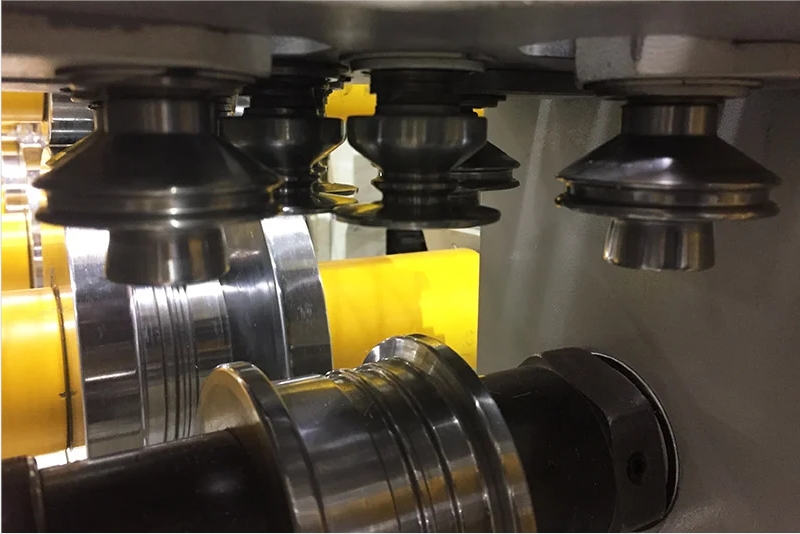

Heavy gauge roll forming machines excel in delivering precision and consistency in the manufacturing process. By utilizing a series of rolls that progressively shape the metal into the desired form, these machines ensure that each component produced meets stringent specifications. This level of accuracy reduces the need for secondary operations such as grinding or machining, thereby saving time and resources. The consistency in the dimensions and shape of the parts ensures that they fit together seamlessly, reducing assembly time and enhancing overall production efficiency.

High-Speed Production Capabilities

Another key advantage of heavy gauge roll forming machines is their high-speed production capabilities. These machines can operate continuously, forming metal at a rapid pace without compromising on quality. This high-speed production allows manufacturers to meet demanding production schedules and increase throughput. By automating the roll forming process, manufacturers can also reduce labor costs and minimize downtime, further optimizing production efficiency.

Cost-Effective Manufacturing Solutions

Heavy gauge roll forming machines offer cost-effective manufacturing solutions by minimizing material waste and reducing the need for additional processing steps. The precision of the roll forming process ensures that material is used efficiently, minimizing scrap rates. Furthermore, the elimination of secondary operations such as welding or riveting reduces labor costs and speeds up the production process. These cost savings can be significant, particularly in large-scale manufacturing operations, contributing to overall production efficiency.

Versatility in Manufacturing Applications

The versatility of heavy gauge roll forming machines is another factor that enhances production efficiency. These machines can be adapted to produce a wide range of shapes and sizes, catering to the diverse needs of various industries. From automotive components to aerospace parts, and from construction materials to agricultural machinery, heavy gauge roll forming machines provide a flexible manufacturing solution. This versatility allows manufacturers to switch between different products with minimal setup time, optimizing production capacity and meeting customer demands promptly.

Scalability and Customization

Heavy gauge roll forming machines also offer scalability and customization options, which further optimize production efficiency. Manufacturers can invest in machines that cater to their specific production requirements, ensuring that they have the capacity to handle current and future demands. Customization options allow for the integration of specific features and capabilities, tailored to the unique needs of the manufacturing process. This scalability and customization ensure that heavy gauge roll forming machines remain a valuable asset in optimizing production efficiency as businesses grow and evolve.

Conclusion

Heavy gauge roll forming machines have become indispensable in optimizing production efficiency across various industries. Their precision, high-speed capabilities, cost-effectiveness, versatility, and scalability make them a valuable asset for manufacturers seeking to enhance their production processes. By leveraging the advantages of heavy gauge roll forming machines, businesses can achieve greater efficiency, reduce costs, and maintain a competitive edge in the global market. As technology continues to advance, the role of these machines in optimizing production efficiency is likely to expand further, driving innovation and progress in industrial manufacturing.