Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 15, 2024 Visit:239 Source:ZCM

The field of heavy gauge roll forming machine design has undergone significant advancements in recent years, transforming the metal forming industry. These innovations have not only improved the efficiency and precision of the roll forming process but also expanded the range of applications and capabilities of these machines. This article explores some of the key innovations in heavy gauge roll forming machine design and their impact on the manufacturing landscape.

Advanced Roll Design and Materials

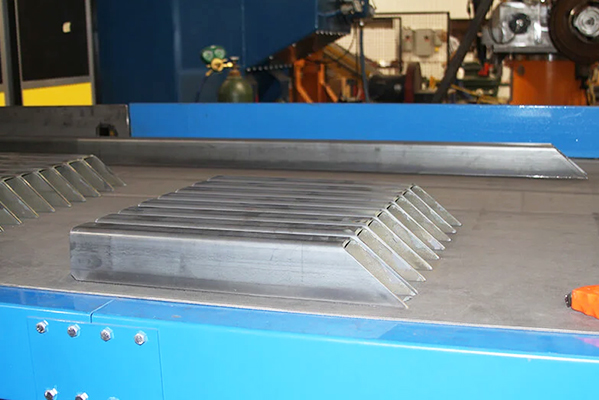

One of the most significant innovations in heavy gauge roll forming machine design is the use of advanced roll materials and designs. Traditional rolls were often made from cast iron or steel, which limited their durability and precision. Modern rolls, however, are crafted from high-strength alloys and composite materials that offer superior wear resistance and thermal stability. These advanced materials enable rolls to maintain their shape and accuracy over longer periods, reducing the need for frequent replacements and maintenance.

Furthermore, the design of rolls has evolved to incorporate features such as crowned profiles and variable-pitch threading. Crowned profiles allow for better metal distribution during the forming process, reducing stress concentrations and improving product quality. Variable-pitch threading, on the other hand, enhances the forming force and control, making it easier to achieve complex shapes and tight tolerances.

Automated and Intelligent Control Systems

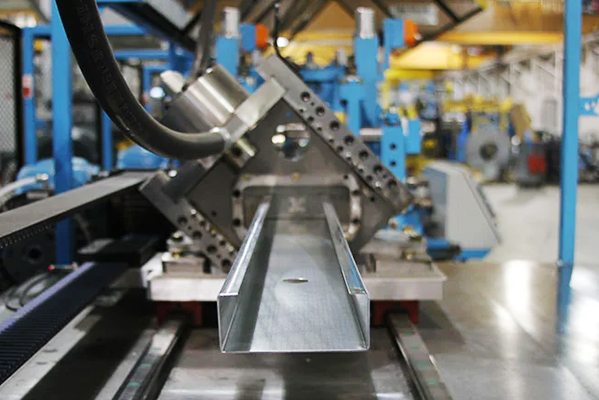

Another innovation in heavy gauge roll forming machine design is the integration of automated and intelligent control systems. These systems use sensors, actuators, and advanced algorithms to monitor and adjust the roll forming process in real-time. By collecting data on factors such as material thickness, temperature, and roll position, these systems can optimize the forming parameters to ensure consistent product quality and minimize waste.

Intelligent control systems also incorporate machine learning algorithms, which enable the machines to learn from past performance and adapt to new conditions. This capability allows for continuous improvement in process efficiency and product quality, making heavy gauge roll forming machines more reliable and versatile.

Modular and Customizable Designs

Modular and customizable designs are another significant innovation in heavy gauge roll forming machine design. Traditional machines were often monolithic, with limited flexibility in terms of configuration and application. Modern machines, however, are designed with modular components that can be easily replaced, upgraded, or reconfigured to suit different manufacturing needs.

This modular approach allows manufacturers to customize their roll forming machines to match specific production requirements, reducing setup time and costs. It also enables them to adapt to new products and technologies as they emerge, ensuring that their roll forming machines remain competitive and relevant in the market.

Enhanced Safety and Operator Interfaces

Safety and operator interfaces have also seen significant improvements in heavy gauge roll forming machine design. Modern machines incorporate advanced safety features such as emergency stop buttons, protective guards, and sensors that detect unsafe conditions and shut down the machine automatically. These features help to minimize the risk of accidents and injuries, ensuring a safer work environment for operators.

Operator interfaces have also become more intuitive and user-friendly. Modern machines are equipped with touchscreens, graphical user interfaces, and diagnostic tools that make it easier for operators to monitor and control the roll forming process. This enhanced user experience reduces the learning curve for new operators and increases productivity by enabling faster and more accurate machine adjustments.

Conclusion

Innovations in heavy gauge roll forming machine design have had a profound impact on the manufacturing industry. Advanced roll materials and designs, automated and intelligent control systems, modular and customizable designs, and enhanced safety and operator interfaces have all contributed to improved efficiency, precision, and versatility in the roll forming process. As technology continues to evolve, the possibilities for innovation in heavy gauge roll forming machine design are likely to expand further, driving progress and innovation in the metal forming industry.