Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 02, 2024 Visit:192 Source:ZCM

The manufacturing industry is constantly evolving, driven by advancements in technology and the relentless pursuit of efficiency and quality. Among the pioneers in this field is a leading heavy gauge roll formers manufacturer, which has recently introduced several innovations in roll forming technology that are reshaping the landscape of metal fabrication.

One of the most notable innovations is the integration of advanced automation systems within the roll forming process. By leveraging robotics and artificial intelligence, the manufacturer has been able to significantly enhance the precision and repeatability of roll formed products. This advancement not only improves the quality of the final product but also reduces the need for manual intervention, thereby increasing overall production efficiency.

Another key innovation is the development of new materials and alloys that can be effectively roll formed using the company's technology. These materials offer superior mechanical properties, such as increased strength and corrosion resistance, making them ideal for use in demanding applications such as automotive components, construction, and aerospace. The manufacturer's ability to work with these advanced materials sets it apart in the market and provides customers with a wider range of options to suit their specific needs.

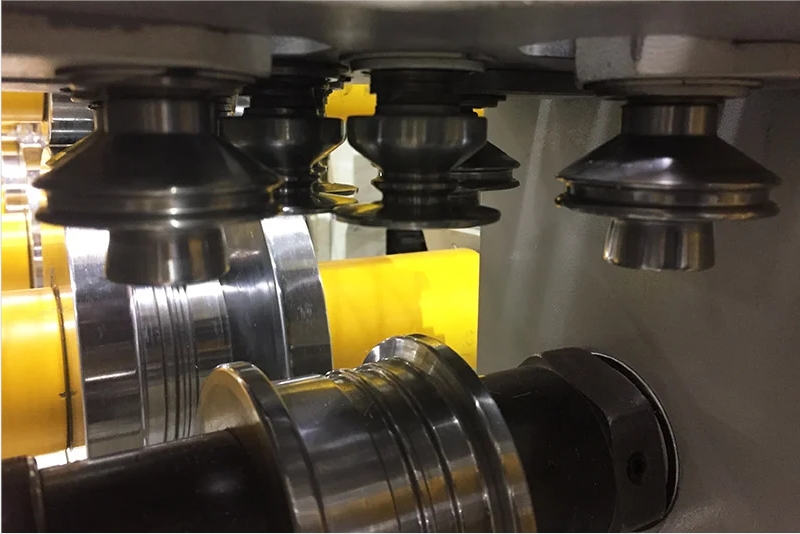

The company has also invested in research and development to create more versatile roll forming machines. These machines are designed to handle a wider range of gauge thicknesses and material types, allowing for greater flexibility in production. This versatility is particularly important in today's market, where manufacturers are often required to produce custom components that meet unique specifications.

In addition to these technological advancements, the manufacturer has implemented new quality control measures to ensure the consistency and reliability of its products. This includes the use of advanced inspection tools and non-destructive testing methods to detect any potential defects or inconsistencies during the production process. By maintaining a rigorous quality control protocol, the company is able to deliver roll formed products that meet the highest standards of customer satisfaction.

The impact of these innovations on the manufacturing industry is profound. By improving the efficiency and quality of roll forming processes, the leading manufacturer is enabling other manufacturers to produce higher-quality products at a lower cost. This, in turn, drives innovation and competitiveness across the entire supply chain.

Moreover, the company's commitment to continuous improvement and innovation sets a benchmark for the entire industry. By investing in research and development, and adopting advanced technologies, the manufacturer is demonstrating that it is not only possible but also necessary to stay ahead of the curve in the rapidly evolving manufacturing landscape.

In conclusion, the innovations introduced by this leading heavy gauge roll formers manufacturer are setting new standards in the metal fabrication industry. By leveraging advanced automation, working with new materials, and implementing rigorous quality control measures, the company is driving efficiency, quality, and competitiveness in the market. As the industry continues to evolve, the manufacturer's commitment to innovation will undoubtedly play a pivotal role in shaping its future.