Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:242 Source:ZCM

In today's competitive manufacturing environment, staying ahead requires continuous innovation and adaptation. A leading professional manufacturer, recognized for its high-quality products and robust production processes, has embraced innovation as a core strategy to boost efficiency across its operations.

The manufacturer's journey towards enhanced efficiency began with a thorough analysis of its existing production processes. By identifying bottlenecks and inefficiencies, the company was able to pinpoint areas where innovation could have the greatest impact. This comprehensive approach ensured that resources were directed towards the most promising initiatives.

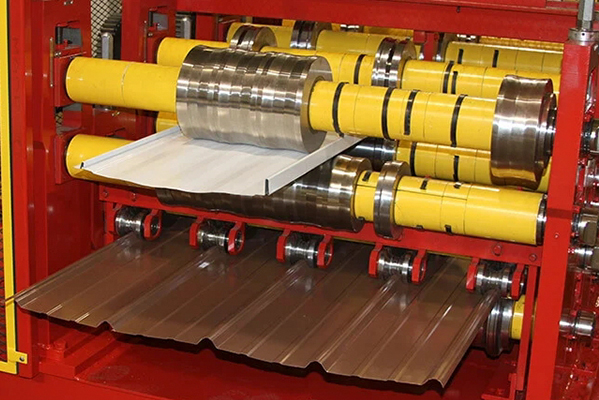

One key innovation involved the integration of advanced automation technology into the production line. The manufacturer invested in state-of-the-art robotic systems and automated machinery that could perform tasks with precision and consistency. This not only reduced the need for manual labor but also minimized errors and increased overall productivity.

In parallel, the company implemented a sophisticated data analytics platform to monitor and optimize production processes in real-time. The platform collects vast amounts of data from various points in the production line, allowing for detailed analysis and quick decision-making. By leveraging this data, the manufacturer was able to identify trends, predict demand, and adjust production schedules accordingly, leading to significant improvements in efficiency and resource utilization.

Another significant innovation was the adoption of lean manufacturing principles. These principles emphasize the elimination of waste and the continuous improvement of processes. The manufacturer worked closely with its teams to identify and streamline unnecessary steps in the production process, resulting in shorter lead times and reduced costs.

The manufacturer also recognized the importance of collaboration and knowledge sharing within its workforce. It established cross-functional teams that brought together experts from different departments to tackle complex challenges and develop innovative solutions. This collaborative approach fostered a culture of innovation and continuous learning, driving further improvements in efficiency.

Furthermore, the company invested in employee training and development programs to ensure that its workforce had the necessary skills and knowledge to operate the new technologies and implement the lean manufacturing principles. This investment in human capital was crucial in harnessing the full potential of the innovations introduced.

The impact of these innovations has been significant. The manufacturer has reported substantial improvements in production efficiency, reduced lead times, and lower operational costs. Customers have benefited from faster delivery times and higher product quality, further enhancing the company's reputation in the market.

As the manufacturer looks to the future, it remains committed to continuous innovation and improvement. By staying at the forefront of technological advancements and embracing new ways of working, it is well-positioned to maintain its competitive edge and continue delivering exceptional value to its customers.

In conclusion, the leading professional manufacturer's embrace of innovation has had a profound impact on its operational efficiency. By integrating advanced automation, leveraging data analytics, adopting lean manufacturing principles, and fostering a culture of collaboration and continuous learning, the company has achieved remarkable improvements in productivity, cost-effectiveness, and customer satisfaction.