Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 25, 2024 Visit:195 Source:ZCM

In the competitive world of manufacturing, where precision and quality are paramount, a leading roll forming machine manufacturer has embarked on a journey to enhance its offerings. By focusing on continuous improvement and adopting advanced technologies, the company is setting new benchmarks in the industry, ensuring that its clients receive machines that deliver unparalleled accuracy and reliability.

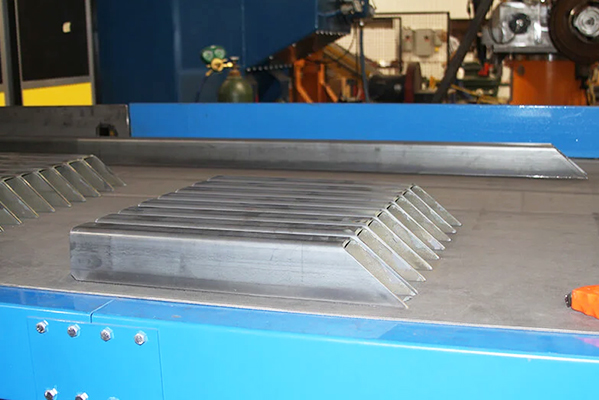

The manufacturer recognizes that product quality and precision are the cornerstones of successful roll forming operations. To meet this standard, the company has invested heavily in research and development, incorporating state-of-the-art design principles and manufacturing techniques. This commitment to innovation ensures that each roll forming machine is engineered to meet the highest standards of precision, capable of producing components with tight tolerances and consistent quality.

One of the key factors contributing to the manufacturer's enhanced product quality is its focus on material selection. By working closely with suppliers and conducting rigorous testing, the company ensures that only the highest-quality materials are used in the construction of its machines. This attention to detail extends to every component, from the rollers and bearings to the control systems and software, ensuring that every aspect of the machine is designed for optimal performance and durability.

In addition to material quality, the manufacturer has also invested in advanced manufacturing processes. By leveraging precision machining and automation technologies, the company can produce machines with intricate details and tight tolerances. This level of precision is critical in roll forming, where even the smallest deviation can affect the final product's quality and performance.

Moreover, the manufacturer has implemented rigorous quality control measures throughout its production process. From initial design and prototyping to final assembly and testing, each stage is subject to strict quality checks and inspections. This comprehensive approach ensures that only machines that meet the company's exacting standards are released to the market.

In terms of precision, the manufacturer's roll forming machines are equipped with advanced control systems and sensors. These technologies enable the machines to monitor and adjust their operations in real-time, ensuring that the roll forming process remains within specified parameters. This level of control not only enhances product quality but also optimizes production efficiency, reducing waste and downtime.

The manufacturer's commitment to enhancing product quality and precision extends beyond the machines themselves. The company offers comprehensive support services, including training, maintenance, and troubleshooting, to ensure that clients can maximize the performance of their roll forming machines. This proactive approach ensures that clients have the resources they need to maintain the highest standards of quality and precision in their operations.

In summary, by focusing on continuous improvement and adopting advanced technologies, the roll forming machine manufacturer has significantly enhanced the quality and precision of its offerings. By working closely with suppliers, leveraging precision machining and automation, and implementing rigorous quality control measures, the company has set a new standard in the industry. This dedication to excellence ensures that clients receive machines that deliver unparalleled accuracy and reliability, driving success in their roll forming operations.