Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 25, 2024 Visit:214 Source:ZCM

Roll forming machines have become a cornerstone in the manufacturing industry, offering a versatile and efficient way to shape metal sheets into a variety of profiles. However, the true potential of these machines lies in their customization options, which cater to the unique manufacturing needs of various industries. By tailoring the roll forming process, manufacturers can achieve precision, efficiency, and cost-effectiveness in producing metal components.

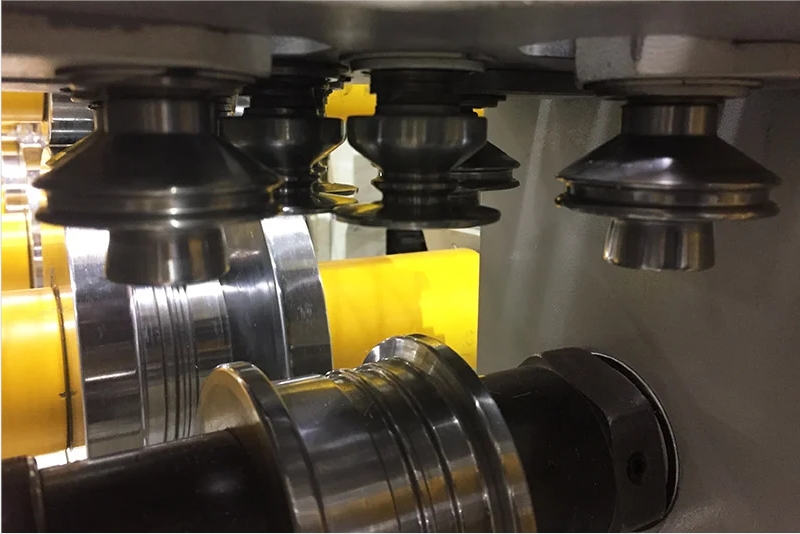

One of the key customization options for roll forming machines is the design of the roll tooling. This refers to the series of rollers that progressively bend and shape the metal sheet. Depending on the desired profile, the tooling can be designed to create intricate shapes, textures, and dimensions. Manufacturers can work closely with roll forming machine suppliers to develop custom tooling that meets their specific requirements, ensuring that the final product meets exact specifications.

Another important customization option is the machine's automation capabilities. Roll forming machines can be equipped with various automation features, such as feeders, conveyors, and robotic arms, to streamline the production process. These features can reduce labor costs, increase production speeds, and improve overall efficiency. By customizing the automation of the roll forming machine, manufacturers can create a seamless production line that meets their unique manufacturing needs.

The material handling system is another area where roll forming machines can be customized. Depending on the size, shape, and weight of the metal sheets being processed, manufacturers can choose from a variety of material handling options. This includes roller conveyors, chain conveyors, and pneumatic conveyors, which can be tailored to fit the specific requirements of the production process. Customizing the material handling system ensures that the metal sheets are fed into the roll forming machine smoothly and accurately, reducing waste and improving product quality.

In addition to these customization options, roll forming machines can also be equipped with various sensors and monitoring systems to ensure precision and quality control. These systems can monitor the temperature, pressure, and speed of the roll forming process, providing real-time data that manufacturers can use to adjust and optimize their production processes. By incorporating these customization options, manufacturers can achieve higher levels of accuracy and consistency in their metal component production.

Another important aspect of roll forming machine customization is the ability to integrate the machine with other manufacturing processes. For example, roll forming machines can be connected to welding, cutting, or coating equipment to create a complete manufacturing line. This integration can reduce handling time, minimize waste, and improve overall productivity. By customizing the roll forming machine to fit seamlessly with other manufacturing processes, manufacturers can create a more efficient and streamlined production environment.

Finally, roll forming machines can be customized to meet specific safety and regulatory requirements. Depending on the industry and the country in which the machine is operating, manufacturers may need to adhere to specific safety standards and regulations. By working with experienced roll forming machine suppliers, manufacturers can ensure that their machines are designed and built to meet these requirements, reducing the risk of accidents and ensuring compliance with regulations.

In conclusion, roll forming machines offer a wide range of customization options that cater to the unique manufacturing needs of various industries. By tailoring the roll tooling, automation capabilities, material handling system, sensors and monitoring systems, integration with other manufacturing processes, and safety and regulatory requirements, manufacturers can achieve precision, efficiency, and cost-effectiveness in producing metal components. With these customization options, roll forming machines can become a powerful tool for meeting the diverse manufacturing needs of today's industrial landscape.