Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 25, 2024 Visit:177 Source:ZCM

In the ever-evolving landscape of manufacturing, the demand for precision, efficiency, and versatility in production processes continues to rise. One industry that has embraced this shift with remarkable ingenuity is the roll forming machine sector. A leading manufacturer in this field has recently announced a series of innovations powered by advanced technology, setting new benchmarks in the metal forming industry.

The manufacturer, known for its commitment to excellence and continuous improvement, has introduced a range of roll forming machines equipped with cutting-edge features. These machines leverage state-of-the-art automation, intelligent control systems, and precision engineering to deliver unparalleled performance.

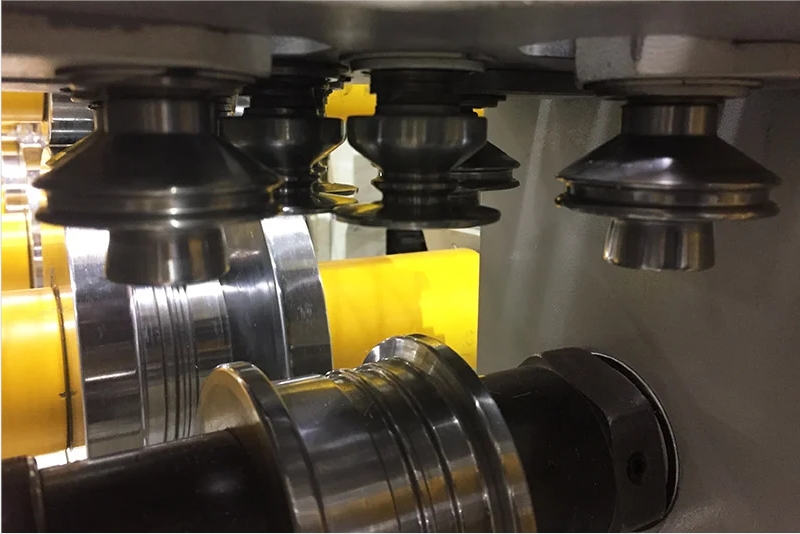

At the heart of these innovations lies the integration of advanced automation technologies. By incorporating high-precision sensors and robotics, the manufacturer has ensured that every aspect of the roll forming process is meticulously controlled and monitored. This not only enhances the accuracy of the finished products but also significantly reduces the margin for error, leading to consistent quality output.

Moreover, the intelligent control systems embedded within these machines utilize advanced algorithms to optimize production parameters in real-time. These systems are capable of analyzing operational data, identifying inefficiencies, and making adjustments to ensure optimal performance. This predictive maintenance capability not only extends the lifespan of the machinery but also minimizes downtime, thereby maximizing productivity.

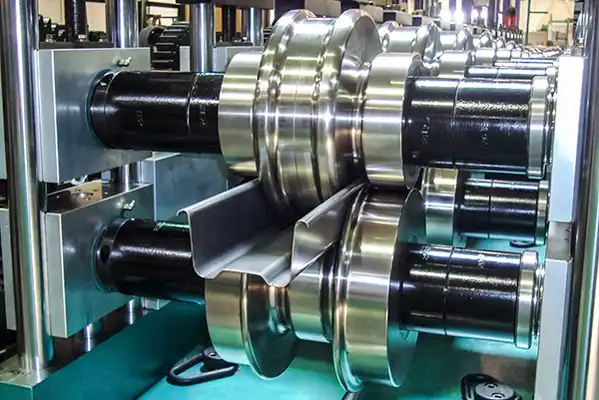

The precision engineering aspect of these roll forming machines is equally impressive. The manufacturer has invested heavily in research and development to create tools and dies that are crafted to the highest standards of precision. This attention to detail ensures that even the most complex shapes and profiles can be achieved with remarkable accuracy and repeatability.

In addition to these technological advancements, the manufacturer has also focused on enhancing the user experience. The machines are designed with intuitive interfaces that make them easy to operate and maintain. This user-centric approach ensures that even operators with limited experience can quickly become proficient in running the machines, further contributing to operational efficiency.

The impact of these innovations is already being felt across various sectors that rely on roll forming technology. From automotive components to construction materials, the enhanced precision, efficiency, and versatility of these machines are enabling manufacturers to produce higher-quality products at a lower cost. This, in turn, is driving competition and fostering innovation within the industry.

Looking ahead, the manufacturer remains committed to pushing the boundaries of what is possible in roll forming technology. With a focus on continuous improvement and a dedication to delivering the best possible solutions for its customers, it is poised to make even greater strides in the future.

In conclusion, the advancements introduced by this roll forming machine manufacturer demonstrate the power of innovation and technology in transforming traditional manufacturing processes. By leveraging state-of-the-art automation, intelligent control systems, and precision engineering, the manufacturer has set a new standard for excellence in the metal forming industry. As these innovations continue to be adopted and refined, they will undoubtedly play a pivotal role in shaping the future of manufacturing.